Below are various smaller products designed and 3D-printed at the company workshop. After sketching and ideation, 3D models are created in Fusion 360, Solidworks or nTopology before being printed in rigid or flexible materials using either FFF or SLA technology.

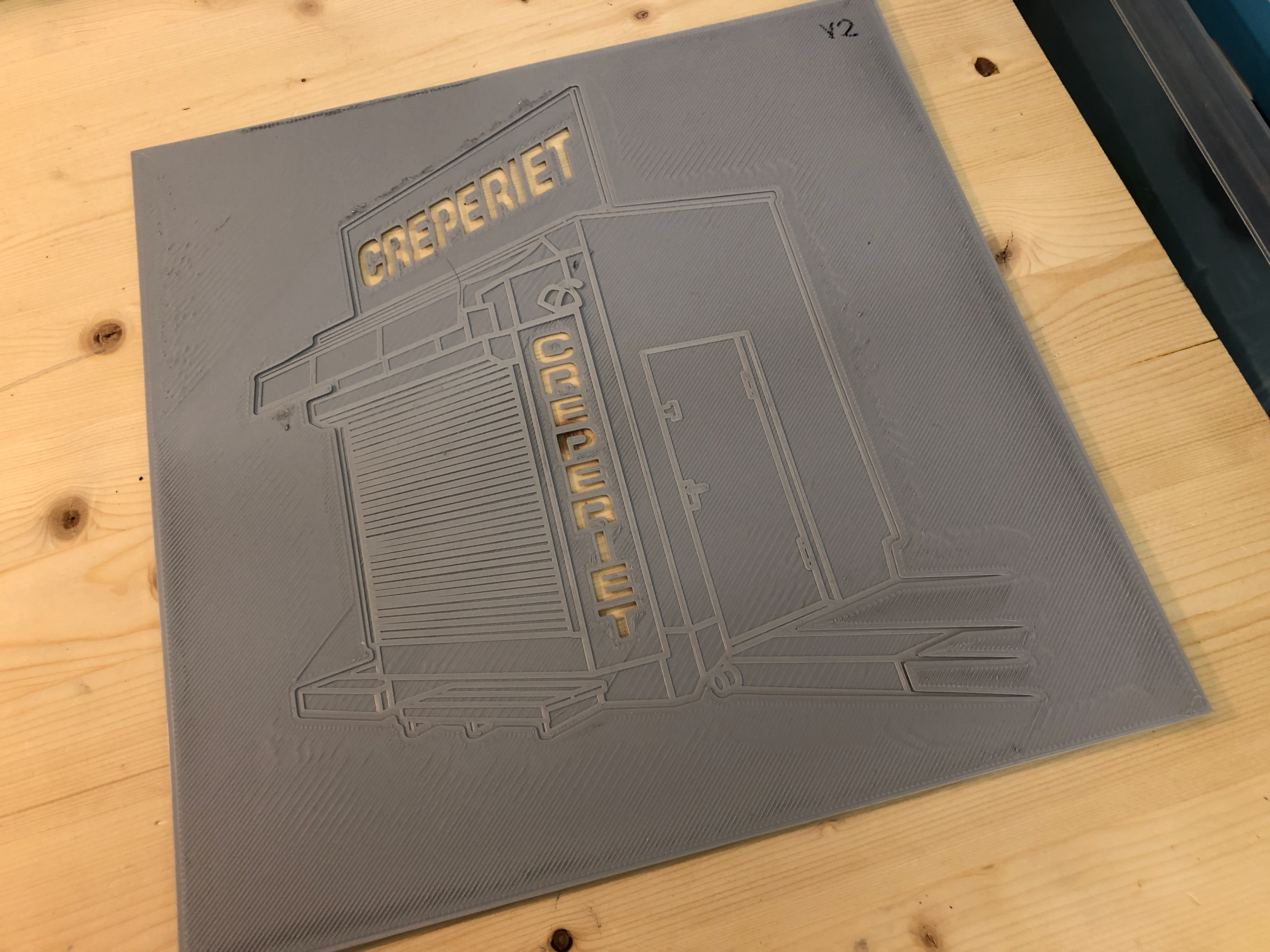

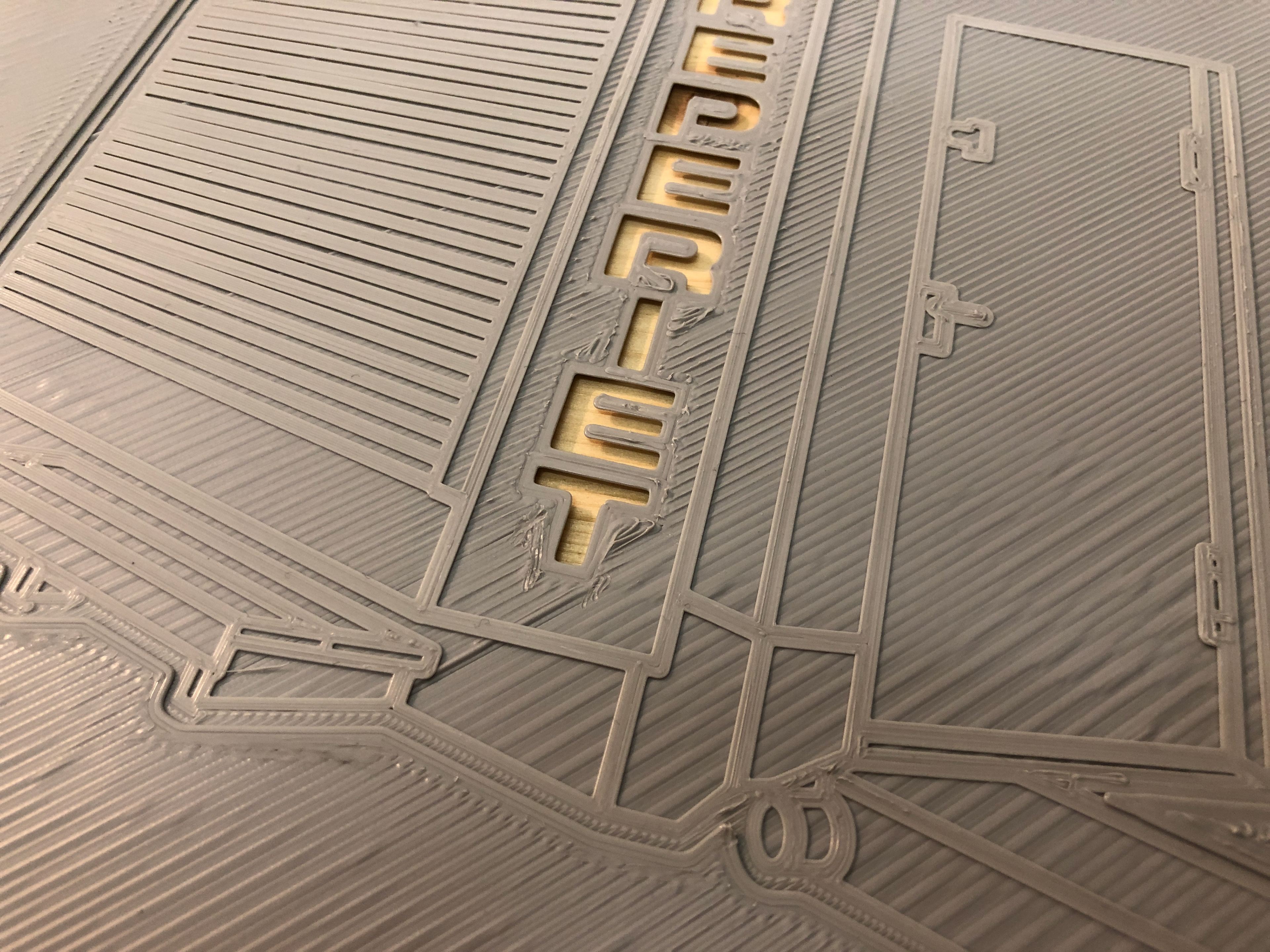

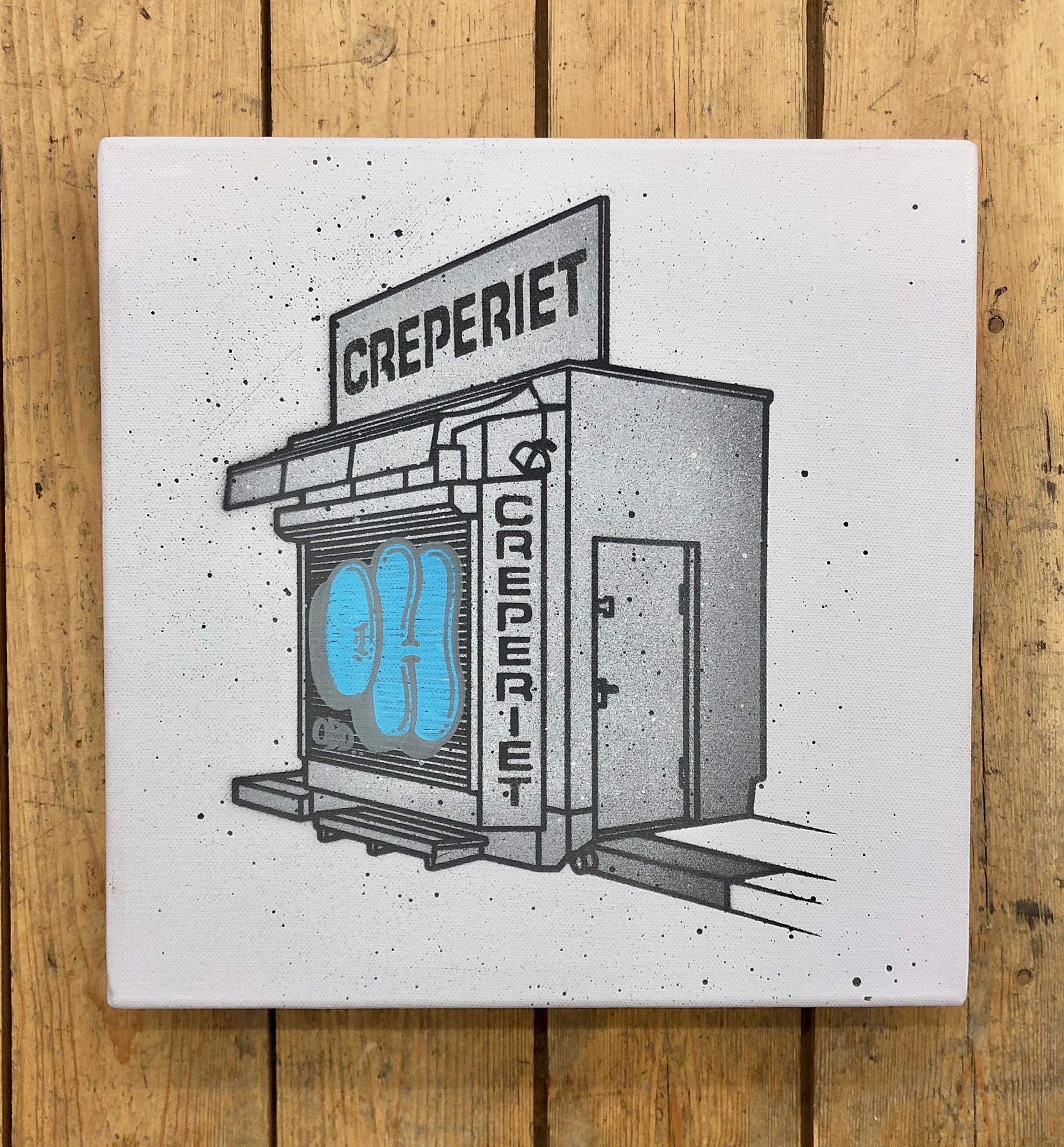

High-detail stencils for artwork

The graphic artist Gorm has been doing stencils by hand for many years to create art and instantly saw the benefits of using 3D printers for creating high-detailed stencils with multiple layers. He sent a vector file with multiple layers that I could turn into printable files. Using PETG the layers came out thin, durable and flexible while having a perfectly flat surface for great control when using spray paint on it. Each stencil lasts for many prints and could easily be reprinted (compared to the original way of doing it by cutting by hand).

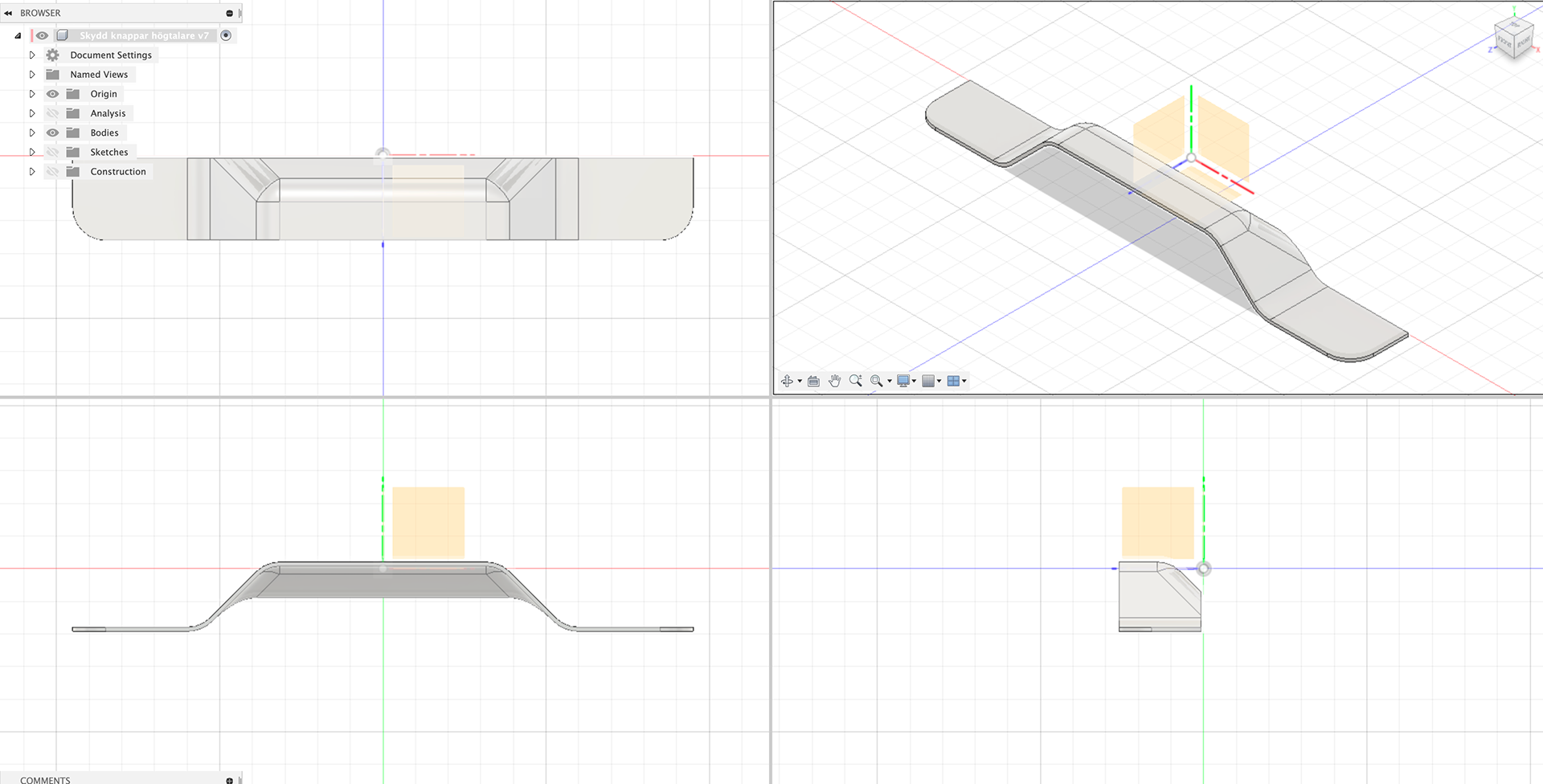

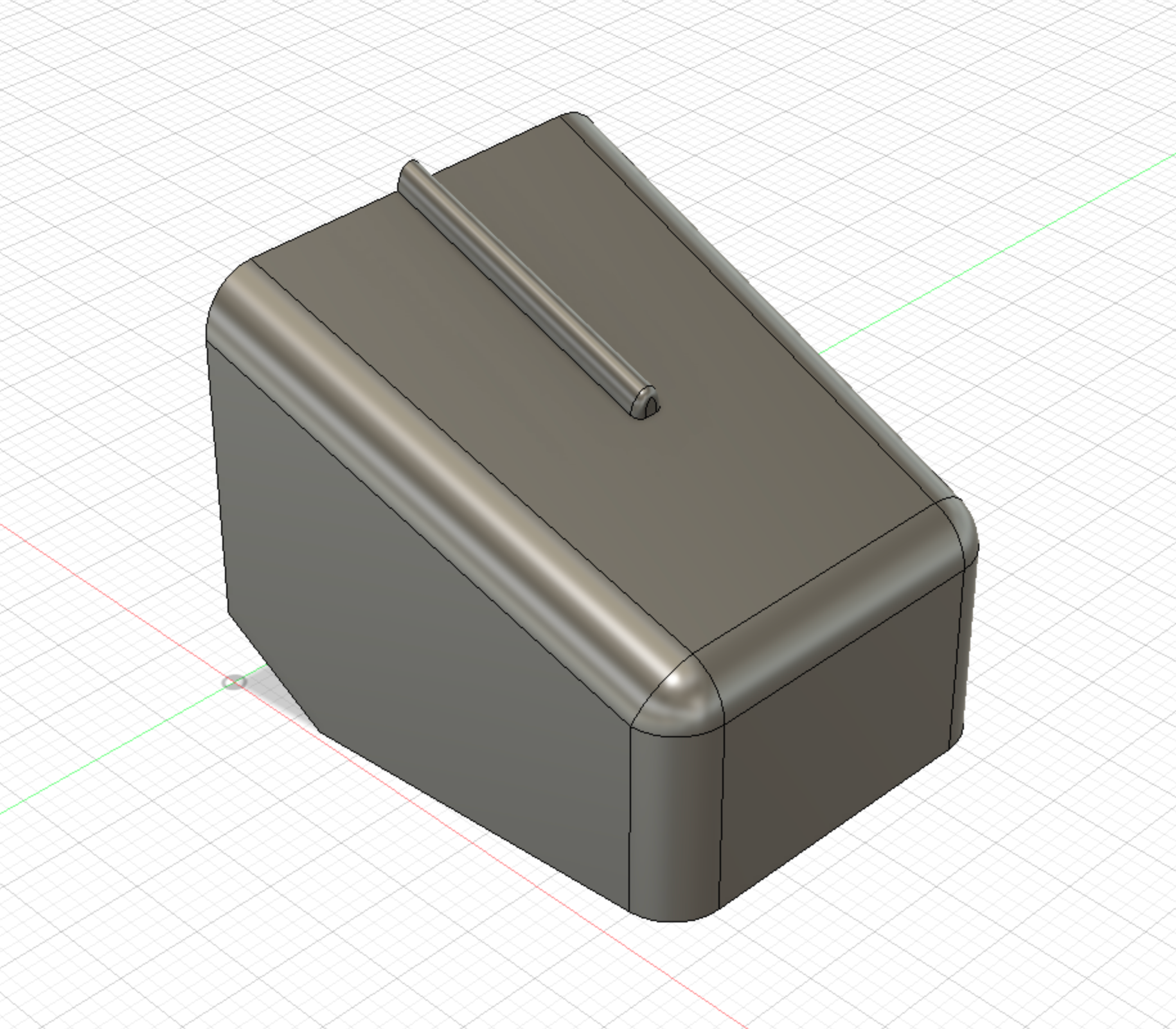

Protective cover above speaker buttons

The clients speaker buttons were often pressed by accident by kittens or young children which gave light to this protective cover that was attached with two-sided tape. The first image shows the first prototype to the left printed in ABS. On the right is the finished part with a high quality semi-glossy finish. The second image shows the installed part.

Spare part for kitchen fan made from scratch

The client had lost the knobs for adjusting fan speed and light so a part was borrowed from another kitchen so that measurements could be made to create an identical 3D model which was printed and sanded in a color that matched the original part.

Bathroom shelf

Custom design to use friction to clamp a shelf in between the existing cupboard and the opposite wall. Printed in plastic and with small rubber feet that was adjusted so the shelf would not slide down under weight.